Contact Us

Tel: 01253 899240

Fax: 01253 899280

Email: sales@gannonoils.com

|

Advanced Search |

View Full-Size Image |

LubricMini 120 Automatic Grease Applicator |

|

|

Price:

Call for Pricing

|

||

| Ask a question about this product | ||

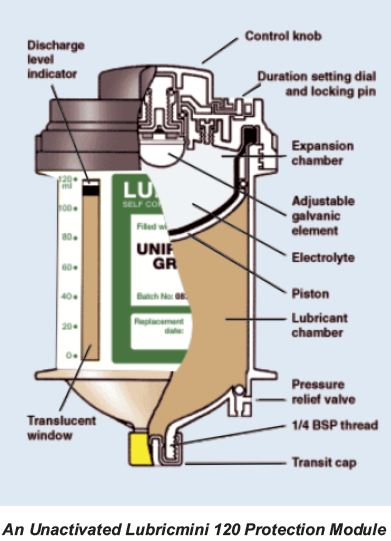

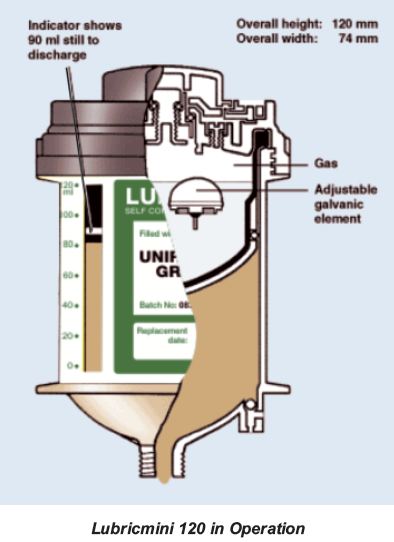

The Lubricmini 120 is a self-ejecting canister of lubricant designed to screw into a grease nipple socket or other lubrication point, and discharge its content of 120ml of lubricant in a controlled continuous flow, for a preselected period of between one month and twelve months. It is driven by gas that is generated by slow galvanic chemical reaction. It is completely self contained and needs no pumps, motors, electricity or compressed air. Once fitted and activated it will work without attention until its allotted lifespan is over.

|

||

Castrol Grease |

Gannon Grease |

Kluber Grease |

Rocol Grease |

Shell Grease |

Texaco Greases |

Last Updated: Saturday, 27 July 2024 01:05

Use in Pressurised Systems

Use in Pressurised Systems